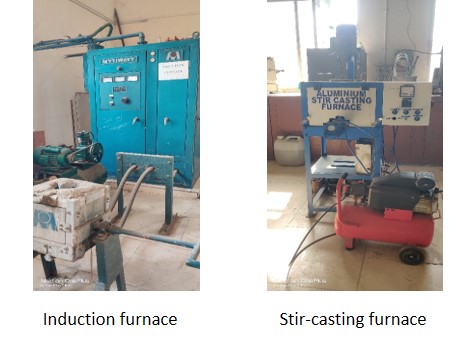

Foundry Engineering Laboratory has important equipments like an induction melting furnace, muffle furnace, sand testing equipment, etc. Several M.Tech and Ph.D. students have completed their projects on sand casting, metal matrix composites, etc., in this laboratory.

In recent years, a set of complete investment casting equipment has been installed in the laboratory, which could enable students to carry out research work on investment casting, starting from wax pattern production, and ceramic shell building to casting and finishing.

In recent years, a set of complete investment casting equipment has been installed in the laboratory, which could enable students to carry out research work on investment casting, starting from wax pattern production, and ceramic shell building to casting and finishing.